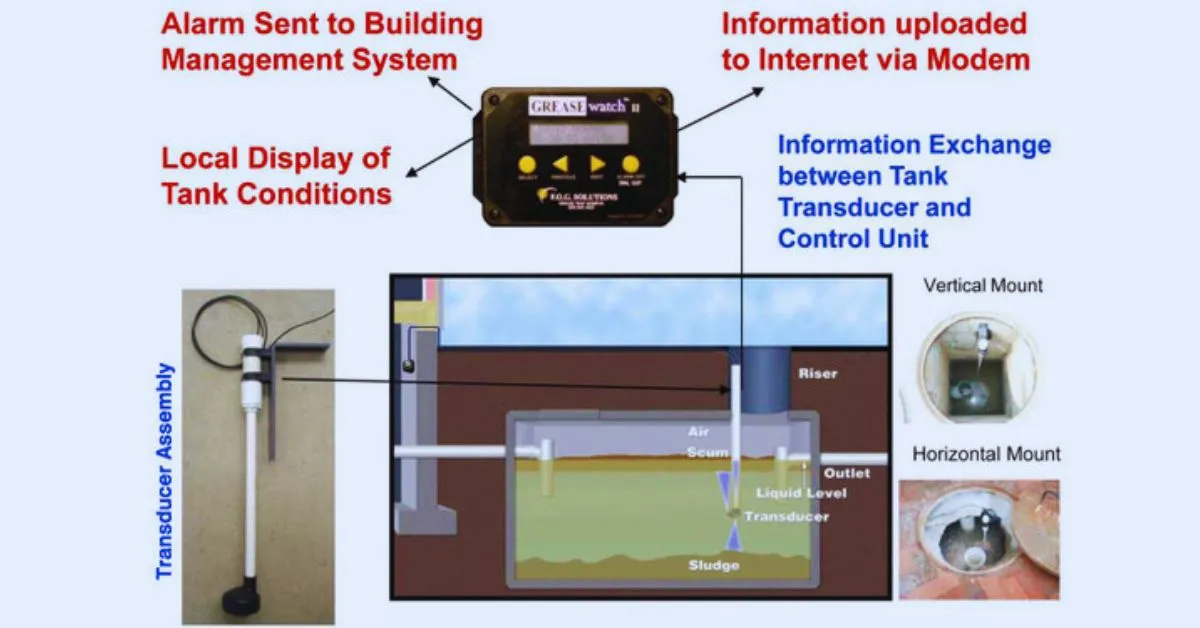

Greasewatch Patent: A Breakthrough in Grease Trap Monitoring

In commercial kitchens and food processing facilities, grease traps are vital for preventing fats, oils, and grease (FOG) from entering the sewer system. However, monitoring these traps efficiently has long been a challenge. Greasewatch, a leader in the industry, has developed innovative solutions that have revolutionized how grease traps are managed. At the heart of this innovation is a patented technology that uses self-calibrating ultrasonic sensors, offering a reliable and advanced alternative to traditional methods.

The Role of Grease Traps in Wastewater Management

Grease traps are essential for capturing FOG and preventing it from clogging pipes and causing environmental issues. These traps intercept grease before it enters the wastewater system, protecting both the plumbing infrastructure and the environment. However, for grease traps to function effectively, they require regular monitoring and maintenance. Traditional methods of monitoring often fall short, leading to inefficiencies and potential problems.

Challenges with Traditional Monitoring Methods

Traditional grease trap monitoring relies on capacitance-based probes, which measure the level of grease by detecting changes in electrical capacitance. While this method works in many cases, it has several limitations. Factors like grease buildup, temperature changes, and the presence of other contaminants can affect the accuracy of these probes, leading to false readings and unreliable data. Over time, these inaccuracies can result in overflows, blockages, and costly maintenance issues.

The Innovation Behind Greasewatch Technology

To overcome the limitations of traditional probes, Greasewatch introduced a new approach using ultrasonic sensor technology. This patented technology utilizes self-calibrating ultrasonic sensors that provide a more accurate and reliable way to monitor grease trap levels. Unlike capacitance-based methods, these sensors measure the distance between the sensor and the grease surface using sound waves, which are less influenced by environmental factors.

How Ultrasonic Sensors Work

Ultrasonic sensors operate by emitting high-frequency sound waves that bounce off the surface of the grease in the trap. The sensor then measures the time it takes for the sound waves to return. This time delay is used to calculate the distance between the sensor and the grease, giving an accurate reading of the grease level. Because the technology is based on sound waves rather than electrical signals, it is less prone to errors caused by grease buildup or temperature fluctuations.

The Benefits of Self-Calibrating Technology

One of the most significant features of Greasewatch’s patented technology is its ability to self-calibrate. This means that the sensors automatically adjust their settings to account for changes in the environment or the grease trap itself. For example, if there is a shift in temperature or the trap’s contents change, the sensor recalibrates to maintain accuracy. This self-calibration reduces the need for manual adjustments and ensures consistent, reliable performance over time.

Advantages Over Traditional Methods

Greasewatch’s ultrasonic sensors offer several advantages over traditional capacitance-based probes:

- Enhanced Accuracy: By using sound waves, the sensors provide precise measurements, reducing the risk of false readings and ensuring that grease traps are maintained only when necessary.

- Increased Reliability: The sensors are less affected by environmental factors such as temperature changes and grease buildup, leading to more consistent performance.

- Lower Maintenance: The self-calibrating feature minimizes the need for manual adjustments, lowering maintenance costs and reducing the likelihood of system failures.

- Durability: These sensors are designed to withstand harsh conditions, making them ideal for use in commercial and industrial settings.

- Regulatory Compliance: Accurate monitoring helps businesses comply with environmental regulations, avoiding potential fines and legal issues.

Impact on the Industry

The introduction of Greasewatch’s patented ultrasonic sensor technology has had a profound impact on the grease trap monitoring industry. By providing a more accurate and reliable solution, the technology has set a new standard for how grease traps should be managed. Businesses that adopt this technology can improve their operational efficiency, reduce maintenance costs, and better protect the environment.

Future Potential

As Greasewatch continues to innovate, the potential for further advancements in grease trap monitoring is significant. Future developments may include even more sophisticated sensors, expanded capabilities for remote monitoring, and integration with broader building management systems. These advancements could further enhance the accuracy, reliability, and ease of use of grease trap systems, making them an essential tool for businesses in various industries.

Conclusion

Greasewatch’s patented ultrasonic sensor technology represents a major advancement in grease trap monitoring. By addressing the limitations of traditional methods, these sensors offer a more accurate, reliable, and low-maintenance solution. This innovation not only improves the efficiency of grease trap management but also contributes to better environmental protection and regulatory compliance. As the technology continues to evolve, Greasewatch is poised to remain a leader in the field, providing cutting-edge solutions for grease trap monitoring.

FAQs:

What makes Greasewatch’s ultrasonic sensors more accurate than traditional probes?

The sensors use sound waves to measure the grease level, which is less affected by environmental factors like temperature changes and grease buildup, leading to more accurate readings.

How does self-calibrating technology benefit grease trap monitoring?

Self-calibrating sensors automatically adjust to changes in the environment or the grease trap, ensuring continuous accuracy without the need for manual intervention.

Why is accurate grease trap monitoring important?

Accurate monitoring helps prevent overflows and blockages, reduces maintenance costs, and ensures compliance with environmental regulations.

What industries benefit from Greasewatch’s technology?

Industries such as food service, commercial kitchens, and food processing facilities benefit from this technology by improving the efficiency and reliability of grease trap management.

What is the future potential of Greasewatch’s technology?

Future advancements may include more sophisticated sensors, enhanced remote monitoring capabilities, and integration with broader building management systems, further improving grease trap monitoring and management.