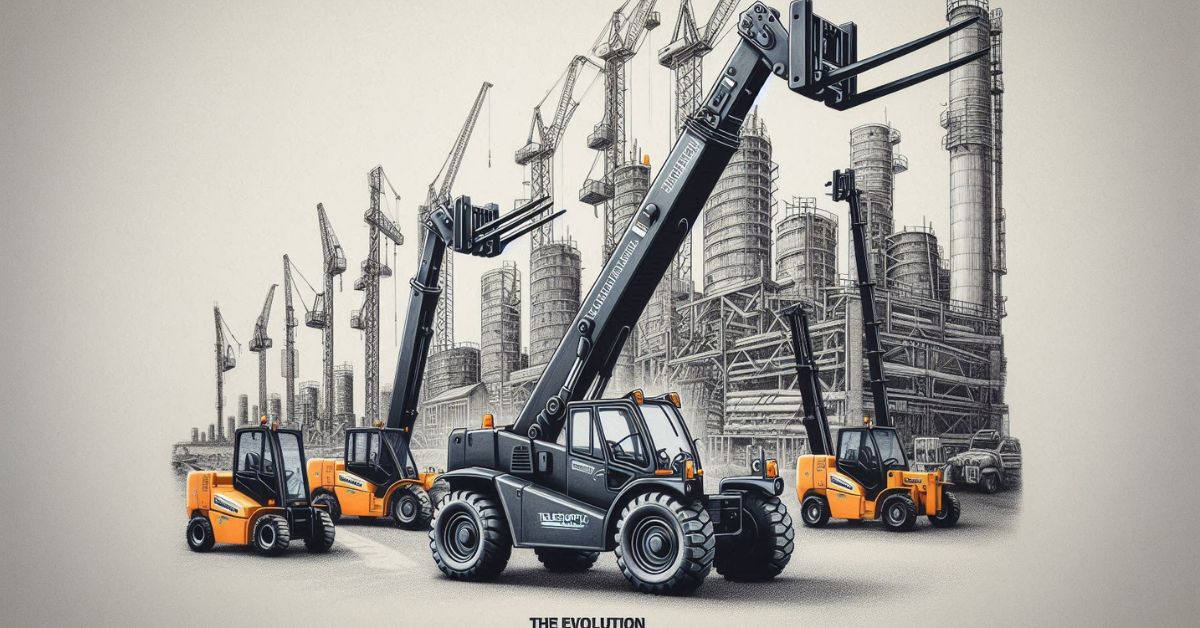

The Evolution of Telescopic Handler Forklifts Since 1957

The world of material handling and logistics witnessed a significant transformation in 1957 with the

introduction of the telescopic handler forklift, also known as the telehandler. This innovative machine

bridged the gap between traditional forklifts and cranes, offering a versatile solution for lifting and

moving materials in various industries. Over the decades, telehandlers have evolved, becoming

indispensable tools in construction, agriculture, and other sectors.

The Birth of the Telehandler

The concept of the telescopic handler forklift was first brought to life by the French company Sambron

in 1957. The original design aimed to enhance the capabilities of standard forklifts by incorporating

telescopic boom, which allowed the machine to extend its reach both vertically and horizontally. This

innovation enabled operators to access areas that were previously unreachable with conventional

forklifts, making telehandlers an instant success.

Design and Functionality

Telehandlers are characterized by their telescopic boom, which can be extended and retracted to

achieve various reach heights and distances. This design feature allows telehandlers to lift loads to

elevated positions or place them at a distance, making them highly versatile. The boom is often

equipped with a variety of attachments, such as forks, buckets, and work platforms, further expanding

the machine's functionality.

The ability to change attachments quickly and easily is one of the key advantages of telehandlers. This

adaptability makes them suitable for a wide range of tasks, from lifting and placing pallets to digging and

scooping materials. Telehandlers are also equipped with stabilizers and outriggers to ensure stability

when lifting heavy loads at extended reaches.

Advancements Over the Years

Since their inception in 1957, telehandlers have undergone numerous advancements in design,

technology, and safety features. Modern telehandlers are equipped with advanced hydraulic systems,

computerized controls, and enhanced safety mechanisms. These improvements have made telehandlers

more efficient, reliable, and safer to operate.

One significant advancement is the integration of advanced hydraulic systems, which provide smooth

and precise control of the boom and attachments. These systems allow operators to perform tasks with

greater accuracy and efficiency, reducing the risk of accidents and improving overall productivity.

Computerized controls have also revolutionized telehandler operations. Modern telehandlers are

equipped with intuitive control panels and digital displays that provide real-time information about the

machine’s performance, load capacity, and operating conditions. These features enable operators to

make informed decisions and optimize the machine’s capabilities.

Safety has always been a top priority in the design and development of telephones. Over the years,

Manufacturers have introduced various safety features to protect operators and bystanders. These

features include load-sensing systems, which prevent the machine from lifting loads beyond its capacity,

and stability control systems, which ensure the machine remains stable during operation.

Applications in Various Industries

Telehandlers have become indispensable tools in several industries, thanks to their versatility and

adaptability. In the construction industry, telehandlers are used for tasks such as lifting and placing

construction materials, transporting heavy equipment, and accessing elevated work areas. Their ability

to navigate rough terrain and reach high places makes them ideal for construction sites.

In agriculture, telehandlers are used for a wide range of tasks, including loading and unloading bales of

hay, moving feed and manure, and handling bulk materials. Their ability to operate in confined spaces

and handle heavy loads, making them valuable assets on farms and agricultural operations.

Telehandlers are also commonly used in industrial and warehouse applications. They are used for tasks

such as loading and unloading trucks, stacking and retrieving pallets, and moving materials within

warehouses and storage facilities. The ability to change attachments quickly allows telehandlers to

perform multiple tasks efficiently.

The Future of Telehandlers

As technology continues to advance, the future of telehandlers looks promising. Manufacturers are

continuously exploring new ways to enhance the capabilities and performance of these machines.

Innovations such as electric and hybrid telehandlers, autonomous operation, and smart technology

Integration is likely to shape the future of telehandlers.

Electric and hybrid telehandlers offer the potential for reduced emissions and lower operating costs.

making them environmentally friendly alternatives to traditional diesel-powered machines. Autonomous

telehandlers, equipped with sensors and artificial intelligence, could revolutionize material handling by

enabling machines to operate independently and perform tasks with minimal human intervention.

Smart technology integration is also expected to play a significant role in the future of telehandlers.

Features such as remote monitoring, predictive maintenance, and connectivity with other equipment

and systems will further enhance the efficiency and productivity of telehandlers.

Conclusion

Since their inception in 1957, telescopic handler forklifts have come a long way. From their humble

beginnings as simple machines with telescopic booms, telehandlers have evolved into sophisticated and

versatile tools that are essential in various industries. As technology continues to advance, telehandlers

will likely continue to innovate and adapt to meet the changing needs of material handling and logistics.