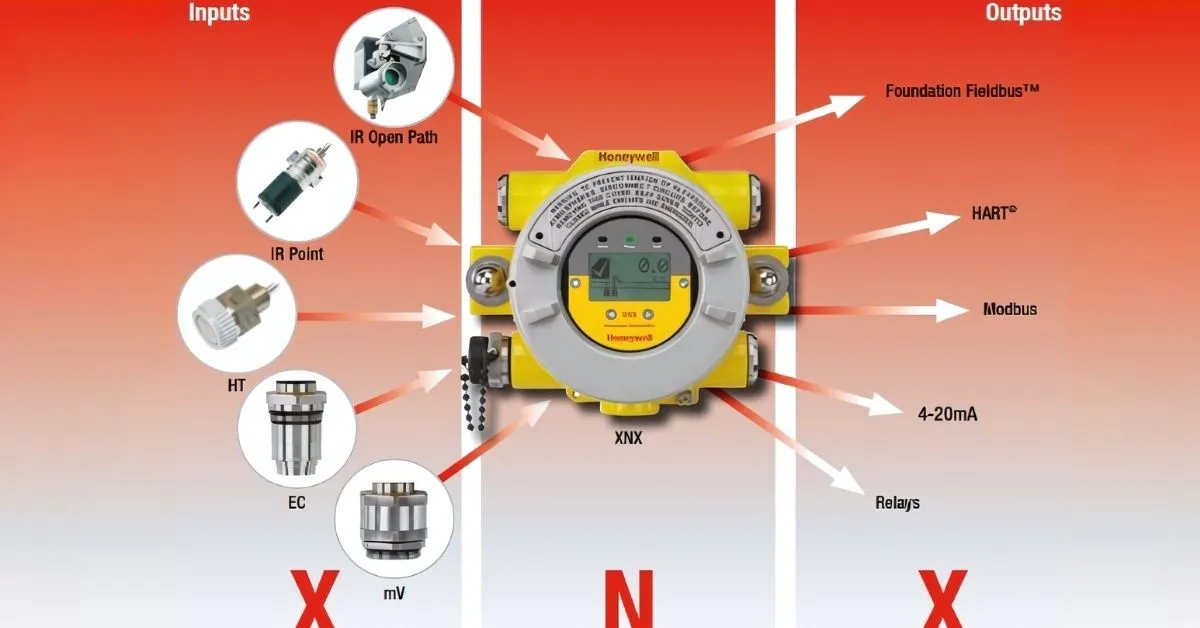

XNX Honeywell Analytics: Advanced Gas Detection Technology

The XNX Universal Transmitter by Honeywell Analytics is a comprehensive and versatile solution designed for industrial gas detection. It serves as a critical component in ensuring safety across various industries by supporting a wide array of sensors and offering a modular choice of inputs and outputs. This transmitter is engineered to integrate seamlessly with other safety equipment, making it a reliable and flexible tool in hazardous environments.

Product Overview

The Universal Transmitter stands out due to its simplicity and low-maintenance design. It operates on a universal platform that is compatible with different gas sensors, including electrochemical, infrared, and catalytic bead sensors. This flexibility allows it to be used across multiple applications, from monitoring flammable gases to detecting toxic substances and oxygen levels. The transmitter is equipped with standard 4-20 mA wiring and HART communication protocols, ensuring easy integration into existing safety systems.

Key Features and Benefits

One of the most significant advantages of the transmitter is its flexibility and adaptability. It supports a wide range of gas monitoring technologies and can be customized with various output options, including Modbus and Fieldbus. The transmitter is designed to meet the stringent safety requirements of industries such as oil and gas, chemical processing, and wastewater management.

Key features include:

- Flammable Gas Detection: Capable of detecting flammable gases in concentrations ranging from 0 to 100% LFL/LEL.

- Flexible Configuration: Supports multiple operation modes, making it adaptable to different industrial needs.

- Ease of Use: The user interface is designed to be intuitive, reducing the need for extensive training.

Technical Specifications

The transmitter is built to withstand harsh industrial environments. It comes in a durable enclosure made from either LM25 aluminum or stainless steel, depending on the application requirements. The unit is designed to operate in a wide temperature range and is protected against environmental elements by its IP66 and NEMA 4X ratings.

| Specification | Details |

| Material | LM25 aluminum (painted), SS316 (optional) |

| Temperature Range | -40° to +65°C (-40° to +150°F) |

| Humidity Range | 20 to 90% RH (non-condensing) |

| Ingress Protection | IP66, NEMA 4X |

| Mounting Options | Surface or pipe mounting (100-150mm dia.) |

Integration and Compatibility

The transmitter is engineered for seamless integration with other safety equipment, making it a versatile tool in industrial safety management. It is compatible with various gas detectors, including Honeywell Analytics’ Searchline Excel, Searchpoint Optima Plus, and other industry-standard gas monitoring controllers. This compatibility ensures that the transmitter can be easily incorporated into existing safety infrastructures, providing a unified interface for all gas detection needs.

Compatible sensors include:

- Electrochemical Sensors: Ideal for detecting toxic gases and oxygen levels.

- Infrared Sensors: Effective for detecting hydrocarbons and CO2.

- Catalytic Bead Sensors: Suitable for flammable gas detection.

Installation and Configuration

Installing the Universal Transmitter is straightforward, thanks to its flexible design. It features two integral mounting lugs on the transmitter body, allowing it to be fixed directly to a surface or mounted on a pipe or structure using a U-bolt and pipe mounting bracket. The transmitter is also equipped with multiple threaded ports, which are available in both metric and NPT versions, providing additional installation flexibility.

Installation process:

- Mounting: Choose between surface or pipe mounting.

- Wiring Configurations: Configure the transmitter for the current source, sink, or isolated outputs.

- Enclosure Options: Select between aluminum and stainless steel based on environmental conditions.

Sensor Compatibility

The transmitter’s ability to support a wide range of sensors makes it a versatile tool for various industrial applications. It can be used with different types of gas detection technologies, including point flammable detectors, toxic and oxygen electrochemical sensors, and open path infrared detectors. This compatibility allows users to deploy the most appropriate gas detection technology for each specific application.

Supported sensors:

- Multi-Purpose Detector (MPD): Measures flammable gases within 0-100% LEL.

- EC Sensor: Detects a wide range of toxic gases and oxygen levels, with the ability to hot-swap sensors without requiring a hot work permit.

- IR Sensor: Suitable for detecting hydrocarbons, methane, and CO2.

Enhanced Safety and Compliance

The Universal Transmitter meets the highest safety standards, making it suitable for use in hazardous environments. It is designed to comply with global certifications, ensuring its safe deployment in various industrial settings. The transmitter’s robust construction and reliable performance make it an ideal choice for industries where safety is paramount.

Safety Certifications:

- ATEX and IECEx Certified: Suitable for explosive atmospheres.

- UL and CSA Certified: Compliant with North American safety standards.

- SIL 2 Certified: Assessed for use in safety-critical applications.

Operational Flexibility

The transmitter offers extensive operational flexibility, allowing it to be configured to meet the specific needs of different applications. It supports various output signals, including 4-20mA, Modbus, and Fieldbus, making it compatible with a wide range of industrial control systems. The transmitter also includes local and remote configuration options, providing users with the ability to adjust settings easily without opening the unit.

Operational features:

- Configurable Outputs: Choose between multiple output signals based on application needs.

- Remote Configuration: Utilize the local HART adapter for easy adjustments and diagnostics.

- Non-Intrusive Operation: Modify settings without needing to open the unit, reducing maintenance time and cost.

Applications in Various Industries

The Universal Transmitter is designed to meet the specific gas detection needs of various industries. Its flexibility and compatibility make it suitable for a wide range of applications, including oil and gas, chemical processing, and wastewater management. The transmitter’s ability to support different gas detection technologies ensures that it can be tailored to the unique requirements of each industry.

Industry applications include:

- Oil and Gas: Monitoring for flammable gases and ensuring safety in upstream and downstream operations.

- Chemical Processing: Detecting toxic gases and ensuring compliance with safety regulations.

- Wastewater Management: Monitoring for hazardous gases and maintaining safe environmental conditions.

Maintenance and Support

Maintenance of the Universal Transmitter is simplified due to its modular design and user-friendly interface. The transmitter is built to be low-maintenance, with features such as hot-swappable sensors and non-intrusive operation, reducing the time and effort required for routine upkeep. Additionally, the transmitter’s robust construction ensures long-term reliability, even in harsh industrial environments.

Maintenance features:

- Hot-Swappable Sensors: Replace sensors without interrupting operations.

- Non-Intrusive Adjustments: Modify settings without opening the unit.

- Durable Design: Built to withstand harsh environmental conditions, reducing the need for frequent maintenance.

Conclusion

The XNX Universal Transmitter from Honeywell Analytics is a versatile and robust solution for gas detection across various industrial environments. Its ability to support a wide range of sensors, combined with its modular configuration options and compliance with global safety standards, makes it an invaluable tool for ensuring safety and efficiency in industrial operations. Whether deployed in oil and gas, chemical processing, or wastewater management, the Universal Transmitter provides a reliable and flexible platform for all gas detection needs.

FAQs:

What types of gases can the Universal Transmitter detect?

The Universal Transmitter is designed to detect a wide range of gases, including flammable gases, toxic gases, and oxygen. It is compatible with Electrochemical, Infrared, and Catalytic Bed sensors, making it versatile enough to monitor gases like methane, hydrogen sulfide, carbon monoxide, and carbon dioxide.

How does the transmitter ensure safety in hazardous environments?

The transmitter is built to meet strict safety standards, including ATEX, IECEx, UL, and CSA certifications. It is housed in a flameproof enclosure made of marine-grade aluminum or stainless steel, ensuring it can withstand harsh conditions in hazardous areas. Additionally, it features non-intrusive configuration options, allowing adjustments without opening the unit, which reduces the risk of exposure to dangerous gases.

Can the transmitter be integrated with existing gas detection systems?

Yes, the Universal Transmitter is designed to integrate seamlessly with existing gas detection systems. It supports standard 4-20mA wiring and HART communication protocols, and it can be configured to work with a variety of gas sensors, including those from Honeywell Analytics and other third-party manufacturers.

What maintenance features does the transmitter offer?

The transmitter is designed for low maintenance, with features like hot-swappable sensors that can be replaced without shutting down the system. Its non-intrusive operation allows for settings to be adjusted using external magnetic switches, reducing the need for regular maintenance checks. The robust construction also minimizes the frequency of repairs.

What industries benefit most from using the Universal Transmitter?

The Universal Transmitter is particularly beneficial in industries where gas detection is critical to safety, such as oil and gas, chemical processing, and wastewater management. Its ability to support multiple gas detection technologies and provide flexible output options makes it ideal for these sectors, where monitoring for a variety of gases is essential.